Product Center

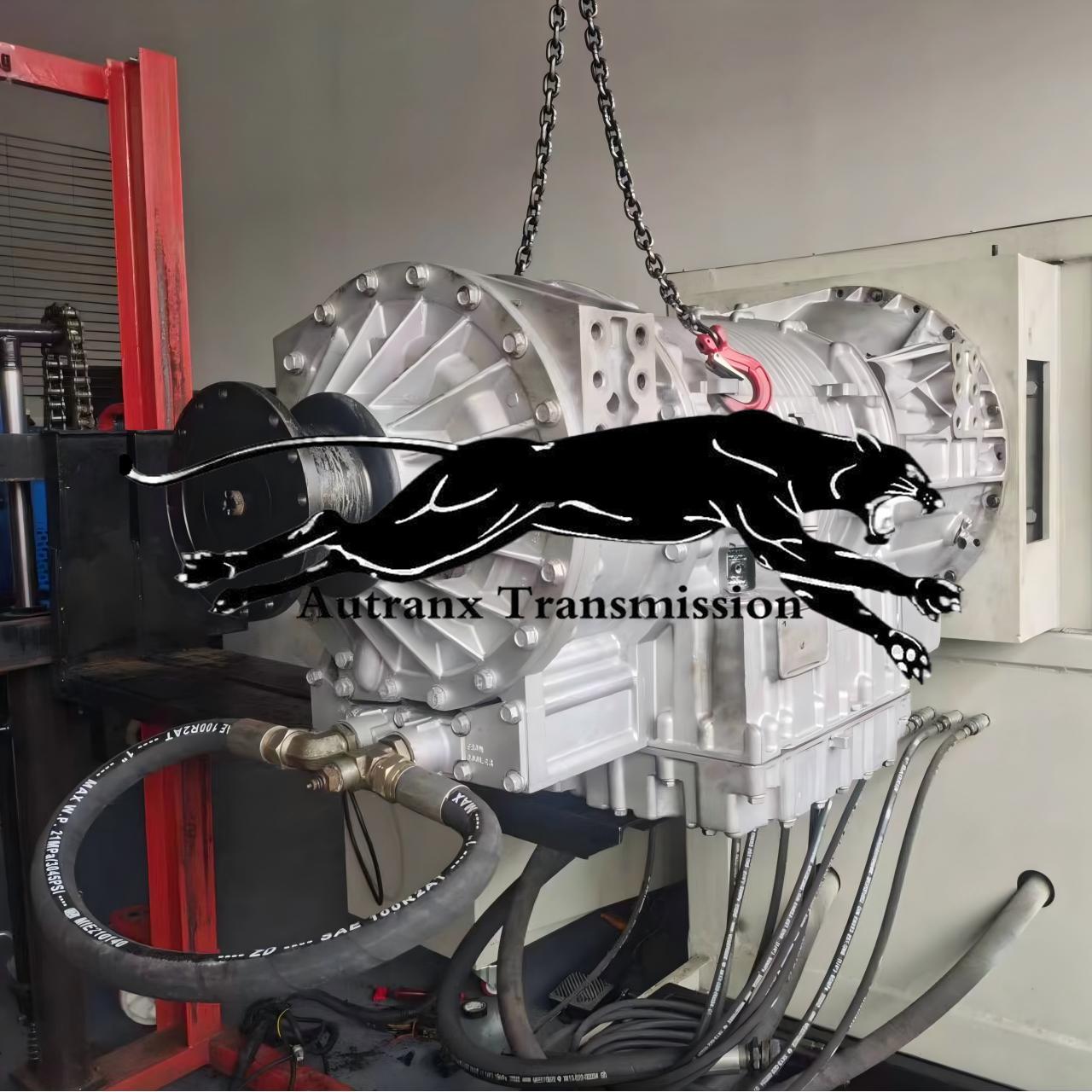

| Name: | Allison Transmission Assembly Oil Field Series 9800OFS / 9800 OFS |

|---|---|

| Description: | Allison Transmission Assembly Oil Field Series 9800OFS / 9800 OFS |

| Part number: | 9800 OFS, 9800OFS |

Product Description

Allison Transmission Assembly Oil Field Series 9800OFS / 9800 OFS

The Allison 9800OFS is a heavy-duty automatic transmission specifically engineered for extreme oil field, mining, and off-highway applications. As part of Allison’s 9000 Series, it’s built to handle ultra-high torque, harsh environments, and continuous severe-duty cycles—making it a top choice for oilfield service trucks, heavy haulers, and specialized industrial equipment.

Key Features of the Allison 9800OFS

✔ 7-Speed Automatic – Optimized gear ratios for heavy loads and steep grades.

✔ Massive Torque Capacity – Up to 2,200 lb-ft (2,983 Nm) input torque (supports engines like Caterpillar C18, Cummins X15).

✔ OFS (Oil Field Series) Design – Reinforced components for:

Extreme dust, mud, and vibration

High ambient temperatures (desert/arctic)

Continuous PTO operation (e.g., frac pumps, cement mixers)

✔ Advanced Cooling System – Dual oil-to-air coolers for sustained high-load performance.

✔ PTO Support – Multiple SAE #1 and #2 PTO openings for hydraulic, pump, or winch drives.

✔ Electronic Controls – Allison TC10™ or WTEC IV with off-road shift strategies.

✔ Dual Hump Sumps – Prevents oil starvation on uneven terrain.

Typical Applications

Oilfield Service Trucks (frac sand haulers, cement trucks, blowout preventer transports)

Heavy Mining & Quarry Dump Trucks

Off-Road Cranes & Drilling Rigs

Military Logistics Vehicles (e.g., Oshkosh HET)

Comparison to Other Allison 9000 Models

| Model | Torque Capacity | Key Use | PTO Support | Cooling |

|---|---|---|---|---|

| 9800OFS | 2,200 lb-ft | Oil field/severe off-road | Yes (dual PTO) | Dual oil-air |

| 9800RDS | 2,200 lb-ft | On-highway heavy haul | Yes | Single cooler |

| 10000OFS | 2,600 lb-ft | Ultra-class mining | Yes | Triple cooler |

Maintenance & Critical Notes

Fluid Requirements: Allison TES-668 or C4 synthetic (change every 500–1,000 hrs in extreme conditions).

PTO Usage: Avoid engagement above 1,200 RPM to prevent damage.

Overheating: Monitor cooler fins for debris clogging (common in oilfield dust).

Rebuild Kits: Use Allison 29578521 for seal/gasket overhauls.

Troubleshooting Common Issues

Erratic Shifting: Check for contaminated fluid or failing speed sensors.

PTO Disengagement: Inspect clutch solenoid or control module.

High Temp Warnings: Verify cooler airflow and thermostat operation.

Need Specifics?

If you require:

Installation diagrams (e.g., for a Kenworth T880 oilfield truck),

PTO gear ratios,

Fault code diagnostics (e.g., "Check Transmission" light),

Provide details—I’ll give you exact technical data!